Your railings and handrails must do more than merely offer support and protection. They must survive rough weather, compliment your architecture, and keep looking good with minimal maintenance. Every metal satisfies these goals in unique ways, allowing project managers to find the precise properties they need from their railing systems.

Geoffrey White

Recent Posts

Structural Steel Fabrication, Metal Fabrication in Norwich, Handrailing Fabrication

The Most Suitable Type of Metal For Outdoor Railings and Handrails

Structural Steel Fabrication, Balustrade Fabrication, Metal Fabrication in Norwich, Handrailing Fabrication

The Top 4 Most Important Considerations When Fabricating Steel Barriers

Whether to navigate traffic or provide security, steel barriers are a valuable addition to many public and commercial spaces. Their close cousin – the security gate – is equally important. When fabricating this type of installation, there are a few important dos and don’ts. Let’s take a look.

Structural Steel Fabrication, Metal Fabrication in Norwich, Handrailing Fabrication

Pros And Cons Of Horizontal Cable Railings

Horizontal cable railings are a trendy option that’s enjoying a comeback as an alternative to metal, wood or glass barriers in residential and commercial properties. Cable railings are horizontal, twisted wire ropes attached to vertical posts made of metal or wood, with a top guard rail for safety and support.

Powder Coating, Shot Blasting, Sand Blasting

Alloy Wheels Refurbishment: Powder Coating Vs Spray Painting

Refurbishing alloy wheels can give a vehicle a completely new lease of life. One of the questions each workshop owner faces is whether to use powder coating or spray painting. Each method comes with advantages and disadvantage for both the shop and the client. Let’s take a closer look at the two approaches.

Many car owners opt for alloy wheel powder coating for its numerous benefits, which include good looks and increased durability. Even though the powder coating process is straightforward, it requires thorough surface preparation to ensure a good coat.

Powder coating has numerous advantages over painting which are impossible to overlook. However, it is more time-consuming than a paint job. How long does wheel powder coating really take?

Grit blasting is a surface preparation method that involves spraying a surface with abrasive grits under high pressure. This blasts away surface contaminants and old paint and prepares a surface for finishing, coating or repainting. Depending on the surface on which the work is being performed, the abrasive media can consist of metallic shards,[...]

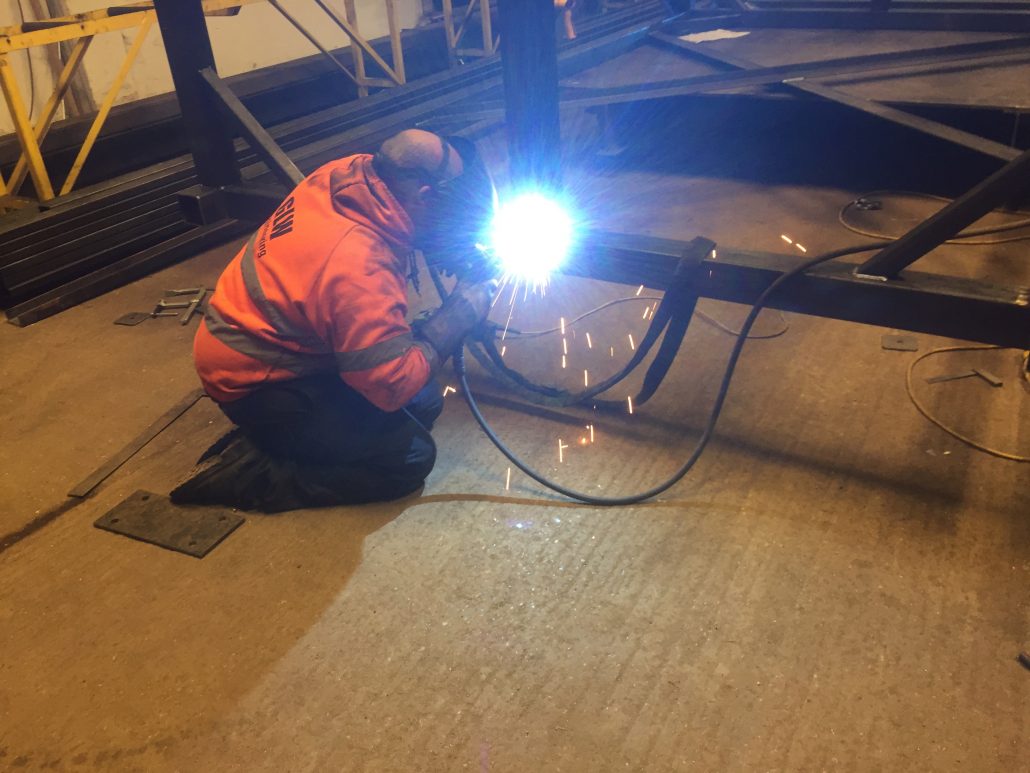

With May 2019 now upon us, its time to take a quick look back at some of our project highlights from the last couple of months!

This article is for any car owner who may be considering getting his or her alloy car wheels powder coated. Our recommendation is, yes, powder coating is a worthwhile investment, which will improve the durability of your alloys, protecting them from scratches and helping them look better for longer.

For the cleaning of industrial equipment, there is simply nothing better than abrasive blasting. This process is one of the best ways to remove rust, paint, oil and other surface pollutants from machinery. Sandblasting used to be the most popular form of abrasive cleaning in the UK, but has now been illegal since 1999. This article explores[...]