Metal fabrication is an umbrella term used to describe the creation of a component, part or structure, out of metal. Metal fabrication typically involves manipulating raw materials, in the form of sheet metal, metal billets, bars or rods, through one or more processes – including, but by no means limited to, cutting, bending and assembly – to[...]

Structural Steel Fabrication, Metal Fabrication in Norwich, Plasma Cutting

What Is Metal Fabrication?

Structural Steel Fabrication, Metal Fabrication in Norwich, Plasma Cutting

3 Stainless Steel Finishing Options

Stainless steel is a hard, strong, ductile material, which is easily fabricated and modified, with excellent resistance to corrosion. Consequently, stainless steel is suitable for a variety of structural and decorative applications in the building sector and elsewhere, but surface finish remains an important consideration.

The majority of[...]

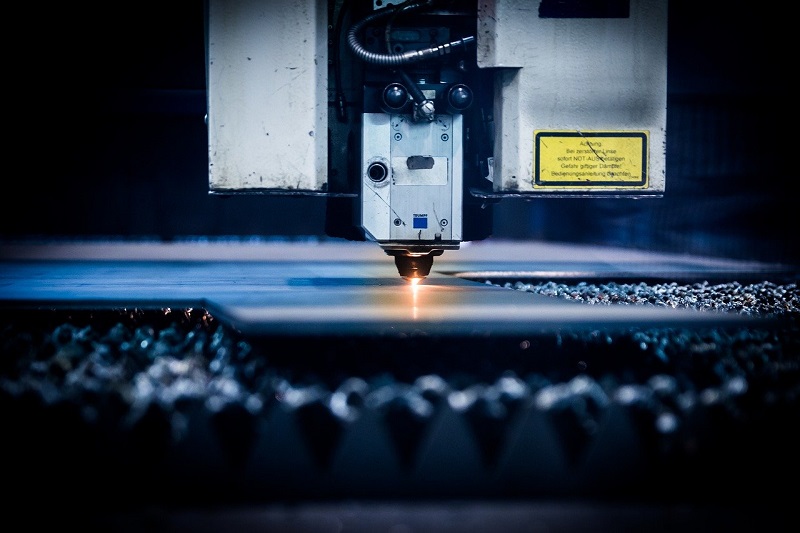

Plasma cutting is a state-of-the-art technique employed to cut metals with superior precision and accuracy. Though once an expensive option, recent advances mean the plasma-cutting process can now deliver ultra-sharp cutting performance with optimal efficiency, which makes the pricing extremely competitive.

Plasma cutting is a high-tech cutting method that uses an ionised, focused jet of gas to slice through thin sheet metal. An internal, high-voltage electrode in the cutter rapidly heats a compound gas mixture to over 20,000 centigrade when switched on. Shielding gas is used as a propellant and barrier to focus and move the induced plasma from the[...]