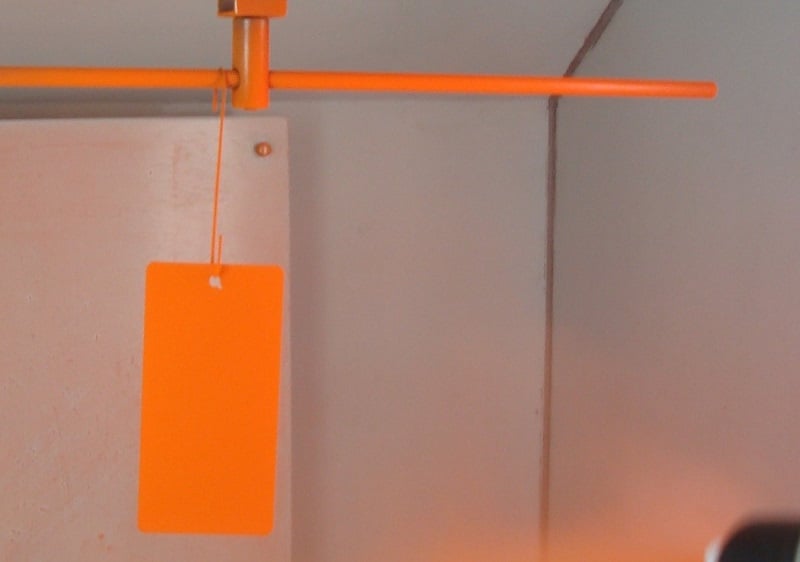

Where there is a compatible metal surface, powder coating is an economic and eco-friendly alternative to liquid-based paints. The benefits of powder coating include the creation of a hard, long-lasting surface, offering solid resistance to heat and chemicals, as well as protection against corrosion and extreme weather.

Compatible & Non-Compatible Metals

Though brass, copper, bronze and titanium will all take a powder coating, the process is most commonly applied to steel and aluminium products, where it yields outstanding results. Provided a metal is capable of holding an electromagnetic charge and will tolerate the high temperatures applied during the curing phase, it will usually be a good candidate for powder coating. Otherwise, the coating will produce a poor finish at best.

Optimum results can be achieved with galvanised steel, stainless steel, mild steel and aluminium, which will all accept a powder-coat finish. These metals can be immersed in an electrostatically charged dry powder mix and then placed in a high-temperature curing oven. The result is a hard, ultra-smooth and durable surface coating, entirely free from blemishes – e.g. unsightly drips or beading. Not only will this coat provide a protective layer, it will also afford a safeguard against impact damage.

Getting The Best Results

To get the best results from powder coating, the critical factor is thorough surface preparation. All contaminants – dirt, grease, paint, chemicals etc. – must be removed before treatment. And finally, do remember that a powder coating cannot simply be applied over an existing protective finish. So any protective layer - such as a chrome finish, for example - must be removed by blast cleaning before the powder coating process can begin.

Cost-Effectiveness

Powder coating is less labour-intensive and therefore more cost-effective than painting. For projects where a fast turnaround is essential, dry-powder treatments can be completed more quickly than would be possible with a liquid finish. Also, unlike liquid spray paints, powder coating does not allow harmful substances to evaporate at the curing stage, which means the process of treating your steel and aluminium avoids any harmful release of VOCs or other hazardous chemicals into the atmosphere.

Next Steps

To discuss how powder coating can add life to your steel components, please get in touch with one of our engineering team today.

Image source: Wikimedia