Grit blasting, of which sand blasting is just one type, is an extremely popular method for cleaning and preparing the surface of an object by removing rust and dirt. It is much faster than sanding the item down by hand and often the abrasive material can be captured and recycled when used with an enclosed cabinet for smaller objects.

What Is Grit Blasting?

It’s process whereby a stream of abrasive material is projected with some force at a target object. The most common medium used is compressed air in normal commercial scenarios but water and other substances, such as gases, are used for specialised manufacturing and scientific applications.

A more extreme form is called shot blasting, where small metal pieces, the size of shot are hurled by the centrifugal force of a rotating disc to both clean and shape a surface (when required). But grit blasting generally utilises a range of non-metal abrasive mediums, from walnut shells to ceramics, sand and grit. The great benefit of this method is that the end result can be greatly varied by using different types, size and hardness of materials. Also, it is a relatively low cost, economical process.

Grit Blasting Steel Furniture

It’s amazing what a difference 15 minutes of grit blasting can make to tired and rusting old benches and other steel furniture. Very often, commercial or public metal furniture stays out in all weathers and over winter, so it’s no surprise that paint soon chips and comes away, leaving patches of metal to rust. Grit blasting is the perfect preparation for a fresh coat of metal outdoor paint that will rejuvenate steel furniture and save you a packet instead of buying a whole new set.

Cars, Lorries And Agricultural Equipment

There comes a point in the life of a vehicle where it has lost its lustre and probably more than just that. Working vehicles, especially, get battered during the course of their normal duties, Truck trailers, are a case in point. When the engine and mechanics are still pretty sound and have years of life still left in them, then it can make sense to overhaul the body and give the entire thing a while new lease of life. The same applies to agricultural machinery. A new coat of paint after sand blasting the old coat and rust off can add many years to its life.

Engine parts & intricate objects

Engines themselves benefit from the general clean-up that grit blasting imparts. While one not want parts such as cylinders or pistons to be sand blasted, for example, because it could impact the internal dimensions if metal were to be shaved off, other abrasive mediums can be used instead on those parts. That highlights one of the benefits of grit basting – adaptability.

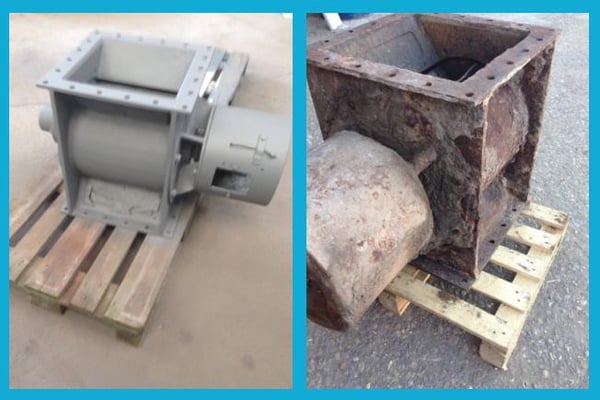

Contract Grit Blasting

At GLW Engineering we undertake all sizes of metal restoration jobs, or even weathering timber for an occasional special project. In addition to shot blasting and grit blasting, our in-house facilities include powder coating, hot zinc galvanizing and soda blasting.

This means that we can cater for the vast majority of requirement with a fast turnaround time. Contact us today and discuss your project or requirements for a quick quote and a quality piece of work that you are guaranteed to be happy with.